Equipment & Facilities

Located inside the Center for Advanced Research Computing, the ARTSLab features an 1100ft² production studio with fully outfitted control room, a 16ft fulldome for immersive projection, and an audio isolation booth for sound recording.

ARTSLab provides access to a range of tools, equipment, and facilities for research, coursework, and creative production. Refer to the Resources & Access Guide for specific user fees and booking procedures.

Fabrication

ARTSLab offers researchers access to multiple digital fabrication technologies. Including the easy-to-use, Glowforge Pro laser cutter that accepts JPG, PNG, SVG, and PDF files. The Glowforge Pro can accept materials up to 19.5” by 11” with a maximum height of 2”.

The X-Carve is a CNC router capable of cutting wood, plastic, and soft metals. It has a work area of 29.5” x 29.5” x 4.5”, and is controlled using an intuitive browser-based system.

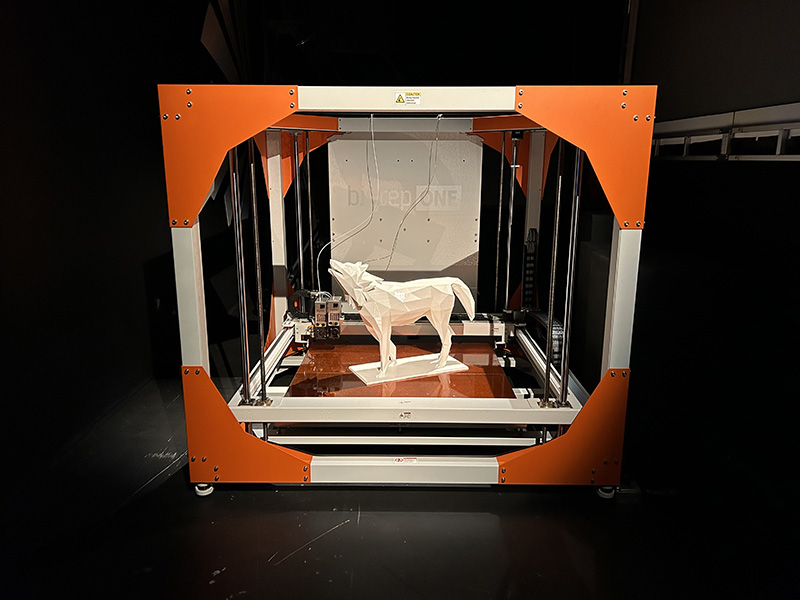

The BigRep ONE is the largest fused deposition modeling (FDM) 3D printer on UNM’s campus. Featuring a massive one-cubic-meter build volume, the BigRep One is perfect for prototyping, production, and a wide range of applications. The ARTSLab BigRep One is equipped with a second extruder, allowing users to print with water-soluble support filament or mix two filaments with different mechanical properties for more complex applications.

The Thread Controller 2 (TC2) is a computer-controlled, hand-operated loom for weaving textiles by hand. While the loom’s operations are completely computer controlled, its hand-weaving feature allows the user to closely monitor every single pick and thus enabling endless possibilities to experiment and innovate with absolute efficiency.

Exhibition

• 30’ x 36’ Usable Floor Space

• 12’ x 40’ Cyc Wall

• 6 Epson Projectors

• 64”w x 120”h Projection Screen

• Mackie TT24 24-Channel Digital Live Mixing Console

• ETC Express 48/96 Control Console

• 5 DMX Mac 250 Series Lights

• 15 Hanging 1K Fresnel Lights

• 20 Hanging 575W Spotlights

Digitization

In recent years, ARTSLab has dramatically increased its capacity to capture three dimensional objects and create virtual models. This includes the acquisition of high-resolution 3D scanners and hardware/software solutions for creating complex photogrammetry of subjects at various scales. These technologies allow us to collaborate with museums and special collections across campus that are interested in digitizing their holdings. It also makes it possible for ARTSLab users to explore what role 3D capture might play in their practice.

The Artec Leo is a wireless and fully standalone professional 3D scanner designed to make scanning as easy and effortless as possible. With embedded AI computing, 5” HD built-in display and battery, it’s the ultimate all-in-one solution for fast, accurate, and high-quality 3D data capture. For objects 20cm – 200cm

Photogrammetry is the science of extracting 3D information from photographs. The process involves taking overlapping photographs of an object, structure, or space, and converting them into 3D digital models. ARTSLab provides researchers with access and training on Agisoft Metashape, an incredibly powerful photogrammetry software.

Photogrammetry becomes difficult with small objects, because detailed images of small objects require Macro lenses that have very shallow depth of field. Thankfully, this can be solved by focus stacking; where multiple photographs of a single object are taken while moving the focus plane through the object and then using post-processing software to combine and blend the images into a single frame that shows the subject in sharp focus from front to back. ARTSLab’s Cognisys StackShot 3x System and Zerene Stacker software help automate and simplify this process.

Printing

Risograph printing is a stencil duplicator that creates vibrant, graphic prints using a process similar to screen printing. The process is known for its unique look and texture, and is often used for posters, zines, comics, and other graphic arts. ARTSLab provides access and training on a RISO MH9450, a two-color digital duplicator that can print up to 150 pages per minute.